Unlocking Efficiency: How Real-Time Concrete Delivery Tracking Can Transform Your Project Management

In the fast-paced world of construction, efficient project management is crucial for meeting deadlines and minimizing costs. A recent report by McKinsey highlights that up to 30% of construction projects experience delays, often due to poor logistics and delivery management. One significant area for improvement lies in Concrete Delivery, where traditional methods can lead to inefficiencies and wasted resources.

By integrating real-time tracking technology into the concrete supply chain, project managers can gain immediate insights into delivery schedules, optimize the use of materials, and enhance coordination among teams. According to a study by the Portland Cement Association, optimized concrete logistics can reduce waste by up to 15%, underscoring the potential for real-time tracking systems to not only streamline operations but also achieve substantial cost savings. This article will explore how embracing advanced tracking solutions can transform project management practices in the construction industry.

Benefits of Real-Time Tracking for Concrete Delivery Efficiency

Real-time tracking for concrete delivery revolutionizes project management by enhancing efficiency and reliability. One of the most significant benefits is the ability to anticipate delays and adjust schedules proactively. With accurate tracking data, project managers can monitor the location and progress of concrete deliveries, enabling them to react swiftly to any unforeseen issues. This real-time insight reduces downtime on construction sites, allowing teams to maintain momentum and adhere to tight deadlines.

Additionally, real-time tracking improves resource allocation and ensures optimal use of materials. By gaining immediate access to delivery status, project managers can synchronize their workforce better and deploy equipment more effectively. The ability to track concrete deliveries enhances communication among team members, leading to improved coordination between various trades on the site. As a result, projects can proceed without the interruptions typically caused by miscommunication or delays, ultimately leading to cost savings and increased overall productivity.

Key Technologies Powering Real-Time Concrete Delivery Tracking

Real-time concrete delivery tracking is revolutionizing the construction industry, spearheaded by advancements in key technologies that enhance project management efficiency. GPS tracking systems are at the forefront, allowing construction managers to obtain precise location data of concrete trucks in real-time. This visibility enables teams to coordinate schedules more effectively, ensuring that materials arrive exactly when needed, thus minimizing downtime and waste.

Furthermore, the integration of Internet of Things (IoT) sensors plays a crucial role in this transformation. These sensors monitor crucial parameters such as concrete temperature and humidity during transit, providing insights that help in maintaining quality. Additionally, mobile applications have emerged as powerful tools that connect stakeholders, from suppliers to on-site managers, facilitating streamlined communication and instant updates on delivery statuses.

Together, these technologies form an ecosystem that not only optimizes logistics but also enhances overall project outcomes by promoting timely decision-making and resource allocation.

Impact on Project Timelines and Cost Management

Real-time concrete delivery tracking significantly impacts project timelines and cost management in construction projects. By enabling precise monitoring of delivery schedules, project managers can effectively align materials with construction phases, minimizing delays caused by waiting for supplies. This integration of real-time tracking systems allows for better forecasting and planning, ensuring that projects stay on schedule and within budget. When materials are delivered promptly, it reduces idle labor costs and the risk of project overruns that often result from insufficient resources.

Moreover, real-time tracking facilitates proactive decision-making by providing essential data on delivery status and potential delays. Project managers can quickly identify discrepancies and engage suppliers to resolve issues before they escalate. This capability not only enhances communication among stakeholders but also fosters a more collaborative environment, ultimately leading to improved cost control. By optimizing the logistics around concrete delivery, organizations can drive efficiencies that have a direct positive effect on both the timeline and the financial aspects of construction projects.

Enhancing Communication Among Stakeholders Through Tracking Solutions

Effective communication among stakeholders is crucial for the success of any construction project. Real-time concrete delivery tracking systems provide an innovative solution to enhance this communication. By enabling all parties—contractors, suppliers, and project managers—to access up-to-date information on concrete deliveries, these systems minimize misunderstandings and streamline the decision-making process. With a shared platform, stakeholders can receive instant notifications about delivery times, potential delays, and any changes in conditions that might affect the schedule.

Effective communication among stakeholders is crucial for the success of any construction project. Real-time concrete delivery tracking systems provide an innovative solution to enhance this communication. By enabling all parties—contractors, suppliers, and project managers—to access up-to-date information on concrete deliveries, these systems minimize misunderstandings and streamline the decision-making process. With a shared platform, stakeholders can receive instant notifications about delivery times, potential delays, and any changes in conditions that might affect the schedule.

Moreover, the implementation of tracking solutions fosters a collaborative environment where everyone is informed and responsive. When challenges arise, such as a delay in delivery, stakeholders can quickly engage in problem-solving discussions, ensuring that the project stays on track. The transparency afforded by these systems helps to build trust among all parties involved, ultimately leading to higher levels of accountability and decreased risk of conflict. By prioritizing efficient communication through tracking, project management can achieve a new level of productivity and reliability.

Case Studies: Successful Implementation of Real-Time Tracking in Concrete Delivery

Real-time concrete delivery tracking has emerged as a transformative tool for project management, significantly enhancing operational efficiency and decision-making processes. Case studies highlight organizations that have successfully implemented this technology, resulting in streamlined logistics and reduced lead time variability. By employing lean logistics principles, these companies optimized their concrete delivery systems, ensuring that materials arrive precisely when needed. This not only minimizes downtime and wastage but also aligns with overall project timelines, resulting in improved productivity.

Moreover, the integration of advanced technologies, such as AI-driven analytics, further amplifies the benefits of real-time tracking in concrete delivery. Organizations have reported remarkable improvements in inventory management and production scheduling through enhanced visibility into their logistics operations. By analyzing data in real time, teams can proactively address potential disruptions, allocate resources more effectively, and maintain a consistent flow of materials. These real-life examples underscore the significant impact that adopting real-time tracking can have, paving the way for a future where project management becomes increasingly efficient and responsive.

Unlocking Efficiency: Real-Time Concrete Delivery Tracking Impact

Related Posts

-

5 Best Strategies for Efficient Concrete Delivery Services

-

What is Concrete Delivery and Why It Matters for Your Construction Project

-

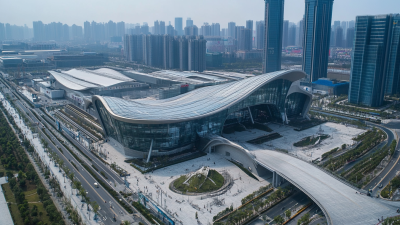

Top 10 Concrete Specialty Manufacturers from China at the 137th Canton Fair

-

How to Choose the Best Concrete Products for Your Global Supply Needs

-

Ultimate Checklist for Sourcing Wholesale River Rock with Cost Effective Strategies

-

Unleashing the Power of Chinese Manufacturing in Best Landscaping Rock Solutions